Technical Specifications:

Working Width: 2000 mm

Main Motor: 7.5 kW

Hydraulic Pump Motor: 1.1 kW

Total Installed Power: 8.6 kW

Net Weight: 6150 kg

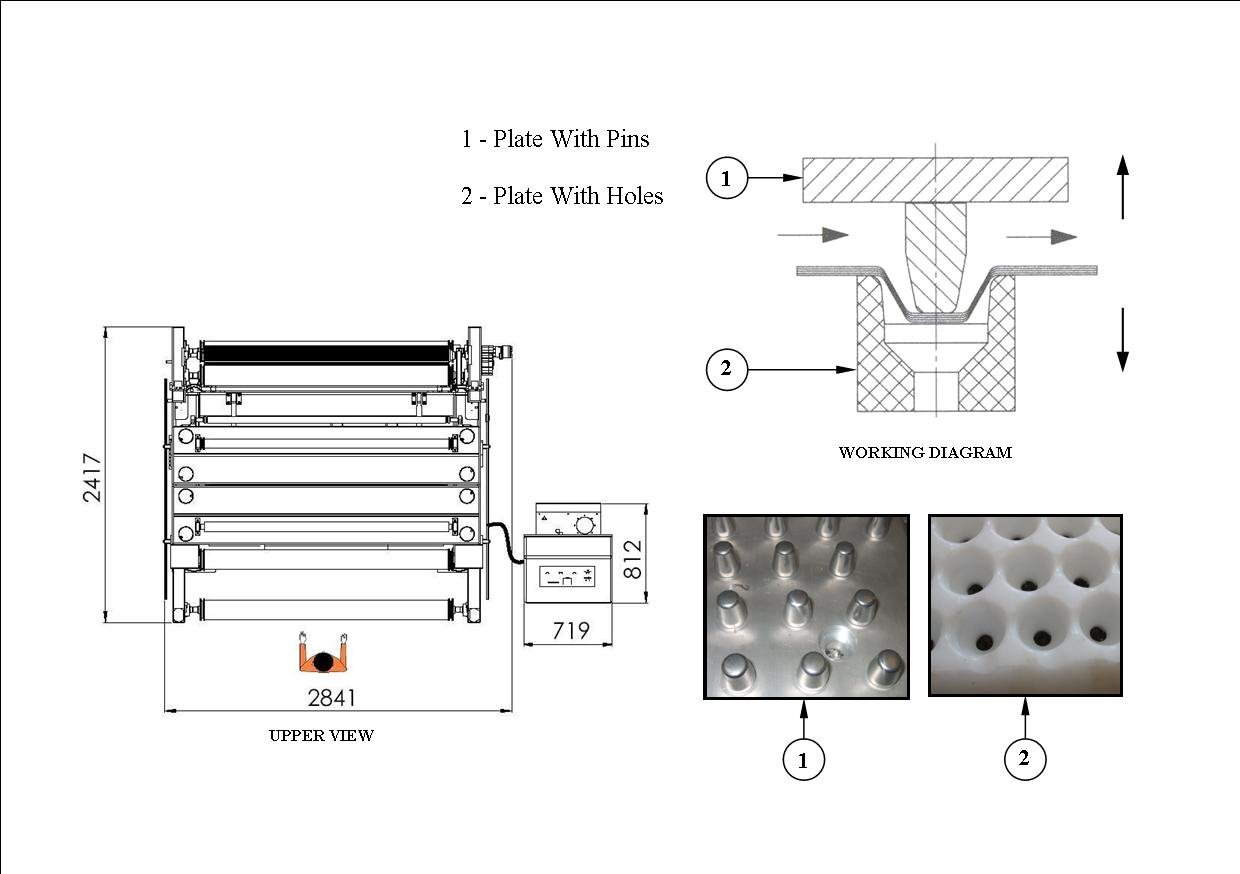

Dimensions: 2841 x 2417 x 1654 mm (L x W x H)

Key Features:

Vibratory Staking Platform: Equipped with two heads (Model A9) for effective spreading and softening of the skin, breaking the grain connections to enhance leather texture.

Versatile Leather Processing: Ideal for a range of leathers, including ovine, bovine, shoe uppers, handbags, calf, vegetable-tanned, crust, and finished leathers.

Precision Control: Features continuous adjustments and visualization of belt speed and working pressure, ensuring optimal control over the staking process.

Dual Beating Jaws: Accommodates various leather types and sizes, allowing for flexible operation.

Robust Construction: The machine’s structure is reinforced to handle significant stress and pressure, ensuring durability and consistent performance.

Advanced Design Elements:

Configuration of Staking Elements: Tailored for handling leathers of different thicknesses, ensuring high-quality treatment without damage.

Shock Absorber System: Minimizes impact during staking, providing a gentle yet effective treatment that maintains the integrity and quality of the leather.

Performance and Usage: The BAM-200 Staking Machine is engineered for tanneries focused on enhancing the quality and finish of their leather products. By integrating advanced mechanical systems and offering versatile adjustments, it stands out as a robust solution for softening and stretching leather, making it ideal for high-volume and diverse leather treatment operations.