Specifications:

Working Width: 4500 x 2600 mm

Table Dimensions: 2600 x 5400 mm

Number of Tables: Options for 2 or 3

Weight:

2 Table Version: 13,800 kg

3 Table Version: 19,000 kg

Air Pressure: 7 bar

Total Installed Power: 25 kW

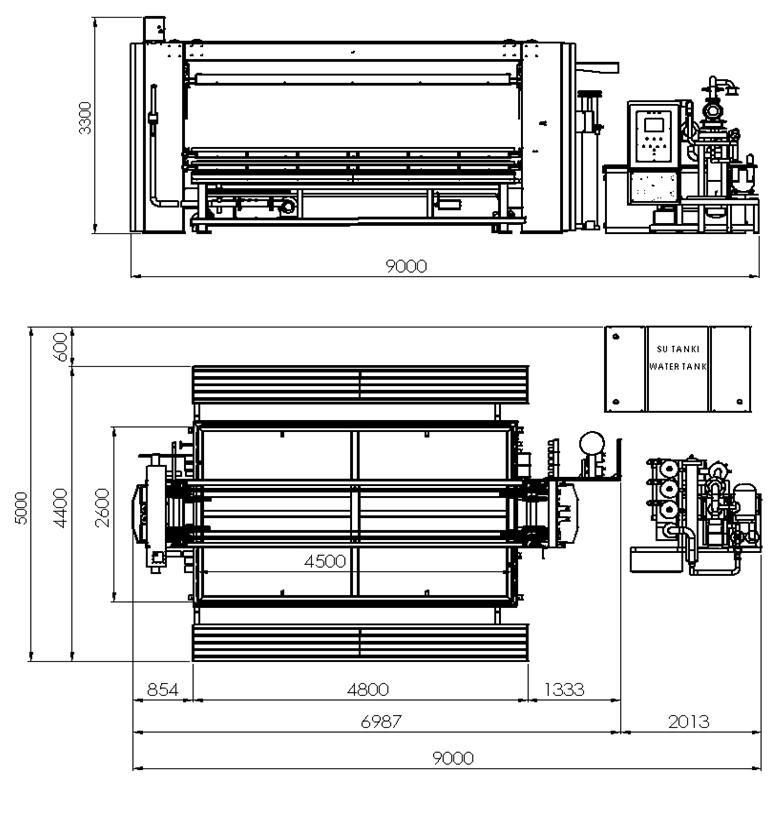

Overall Dimensions: 9000 x 5000 x 3300 mm

Motors and Power:

Turbine Motor for Hot Water Feeding: 2.2 kW

Pump Motor for Cold Water Turbination: 1.1 kW

Water Circulating Vacuum Pump Motor: 15 kW

Turbo Motor of the Blower Pump: 2.2 kW

Fan Motor of the Cooling Tower: 3 kW

Pump Motor of the Cooling Tower Circulation: 1.5 kW

Construction and Design:

Material: Tables are covered with 8 mm thick stainless steel, available in shiny or matte finishes to accommodate customer preferences.

Operation: The machine operates pneumatically, ensuring efficient and consistent performance.

Filter System:

Configuration: Features a layered filter system from bottom to top:

Complete vacuum belt

Thick complete plastic filter

Thin complete plastic filter

Material: Filters are crafted from plastic for ease of cleaning and minimal paint retention, facilitating quick color changes during processing.

Vacuum and Cooling Systems:

Efficiency: Utilizes a water ring pump effective up to 760 millibars, with a blower pump enhancing up to 950 millibars, ideal for materials requiring lower temperatures, such as vegetal and goat skin.

Cooling Technology: Includes heat exchangers and separators for cooling gases post-vacuuming to ensure effective condensation.

Control and Adjustments:

Automation: Table level adjustments are automated for precision.

Operator Panel: Features a touch pad for controlling vacuum level, table temperature, and heating/cooling settings, allowing direct interface adjustments.

Performance and Usage:

Application: Primarily used for uniform drying and material quality enhancement through vacuuming, making it ideal for high-standard leather processing.

Versatility: Engineered to handle various skin types, ensuring high-quality finishes and consistent material quality.