Technical Specifications:

Working Width: 1300 mm

Main Motor: 15 kW

Rubber Roller Drive Motor: 0.37 kW

Rubber Roller Approaching Motor: 0.10 kW

Fan Motors: 3 kW and 1.1 kW

Conveyor Belt Motor: 0.37 kW

Total Installed Power: 19.94 kW

Net Weight: 1600 kg

Dimensions (L x W x H): 2100 x 2240 x 1470 mm

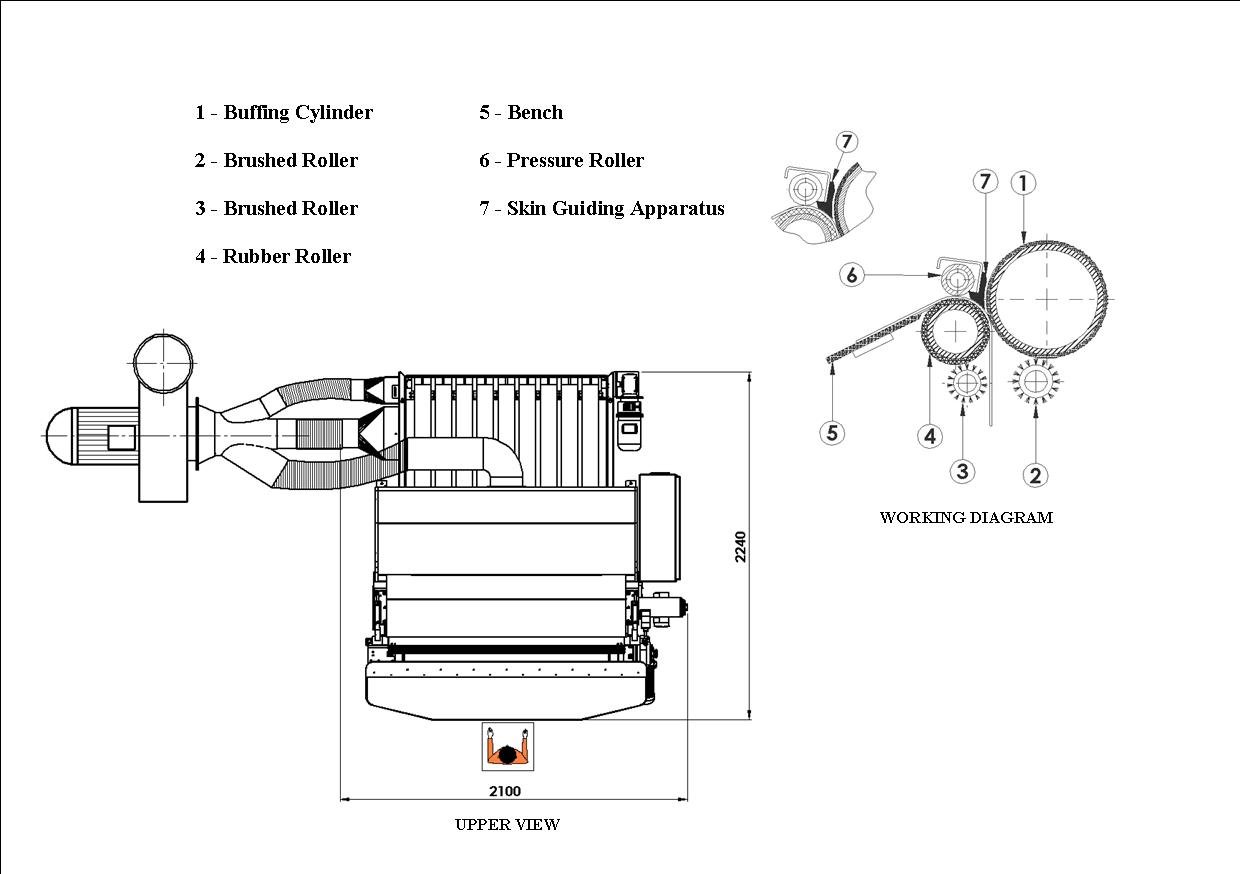

Machine Description:

Suitability: Designed for the buffing operation of unwollen skins, making it ideal for processing various types of leather materials.

Features and Components:

Buffing Roller: The main roller of the machine, which is wrapped with buffing paper pre-determined according to the desired grit standard. This roller is critical for achieving the required texture and thickness reduction.

Rubber Sleeve Roller: Assists in feeding material by spreading it evenly before it reaches the buffing roller.

Brush Rollers: Two brush rollers enhance the machine's functionality:

The first is located under the rubber roller, aiding in the feeding operation by stripping the skin from the rubber roller and cleaning the rubber sleeve.

The second brush roller, located under the buffing roller, facilitates the stripping of material from the main roller and supports the transport process.

Holding System: Comprises two parts:

Skin Guiding Apparatus: Pneumatically activated and made of aluminum, it holds the skin delicately to ensure even buffing across the entire surface.

Pressure Roller: Applies consistent pressure to maintain the skin's position during processing.

Operational Efficiency and Safety:

The rubber sleeve on the roller is easily replaceable by air pressure, ensuring quick maintenance and adjustments.

Buffing paper replacement is straightforward, allowing for rapid changes between operations.

Equipped with several safety components, including an air safety hose, hand touch safety tube, and cover locks, to ensure the machine operates safely under all conditions.

Usage: This buffing machine is an essential tool for tanneries looking to refine the finish of leather products, particularly for high-end applications like nappa leather, ensuring a consistent and high-quality finish across different leather batches.